A Modern Alternative For Anti-Corrosion Protection

The relatively new on the scene, Polyurea two-component thermosets are chemically similar to the polyurethanes and are offered as aliphatic and aromatic applications. They are produced by the response of an isocyanate with an amine resin part instead of a polyol, just like polyurethanes. Polyureas can be used on their own or as hybrids with polyurethanes. They treat every readily to form soft to hard elastomers for usage on concrete floors or containments. They have the same benefits as %100 solids high-build coatings. Polyaspartic variations produce aliphatic items with longer pot lives to be applied by brush, roller, or spray.

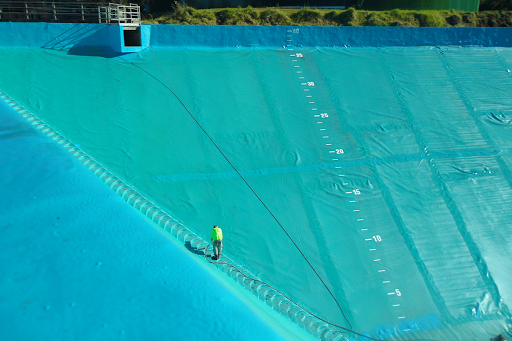

Polyurea spray coatings technology is among the greatest advancements of the last 20 years. This innovation combines quick treating, even at extremely low temperatures, and water insensitivity with remarkable mechanical residential or commercial properties, chemical resistance, and durability.

The advancement of new basic materials and enhanced spray equipment has made it possible to overcome the preliminary issues of this innovation, such as substrate wetting, inter-coat adhesion, and complete surface area quality.

The latest advancement programs focus on extending the application fields through the introduction of MDI-prepolymers combining low viscosity with low NCO content, resulting in slower reactivity and greater flexibility. Additionally, prepolymers with higher NCO content produce coatings with remarkable hardness.

Inevitably coatings get harmed by external forces or by several long-lasting degradation procedures that impact the coating constituents. Normally this results in coating defects that expose the pipe steel to the environment around the pipeline, and this corrosion risk is and can be managed by cathodic protection.

Polyurea polymers are created to compete with tri-laminate products such as FBE, 3LPP, and 3LPE, offering greater performance coatings at competitive costs. The application processes required are basic and efficient and the equipment systems used are low-cost when compared to the costs of systems utilized in the application of FBE, Tri-Laminate, and similar coating technologies and not to mention the field joints which works on all of the above with added benefit of cost, speed and minimum back to service time.

Polyurea is characterized by lots of vital properties, which make it an efficient corrosion-resistant coating.

Water-resistance is perhaps the essential characteristic considering that water, as a universal solvent, in the mix with other materials can take various types and can create a destructive environment and have a destructive impact on the steel substrates. The incredibly low water absorption rates and moisture vapor transfer are necessary functions that make it a reliable coating barrier that extremely few coating can match.

The dielectric strength is a crucial home of Polyurea, which helps break the electrical circuit established during corrosion response and makes it suitable to be used as a corrosion-resistant coating by resisting the passage of electrons. Polyurea has a dielectric strength of > 16 VK and this integrated with low moisture absorption makes it an ideal anti-corrosion coating.

Polyurea coating’s high resistance to ionic passage is the desired coating particular and avoids transfer or passage of chlorides, sulfides, or similar ions, which speeds up corrosion. Resistance to ionic passage is a contributing element to chemical resistance, and Polyurea is good for chemicals in between pH 12 and pH four, especially the alkalis.

The strong adhesion prevents the problem caused by a temperature gradient, osmosis, and electro-osmosis and keeps its integrity for a longer time, therefore boosting the coating life. A strong adhesion also avoids undercutting.

A well-developed elastomeric Polyurea has good resistance to abrasion, impact, and searching. The loss is < 6mg on the C17 wheel, comparable if not much better than most of the anti-corrosive coatings being purchased from today.

Among the characteristics that make Polyurea special is its retention of physical residential or commercial property on aging, making it weather and age resistant and making it suitable as a coating for long-term protection. A well-formulated Polyurea keeps more than 90% of its physical characteristics, even after aging.

Polyurea and cathodic protection are a great way to keep steel pipelines from rusting on the outside. The coating provides the first and significant defense against corrosion. In case of its damage, the cathodic protection serves to prevent pitting or basic corrosion where the pipe steel is exposed by damage to the coating. Coating damage is to be anticipated on all pipelines using conventional coatings, and the degree of damage with Polyurea is very little or none unless these are very roughly handled. For this reason, the degree of risk is less.

A good protective coating application always boils down to preparing the substrate or product it is applied to. Preparation is typically in the form of shot blasting or ultra-high water blasting, depending upon where the application is to happen and the product it is to be applied to. There are cold-used solutions that can be used utilizing a brush, roller, or squeegee.

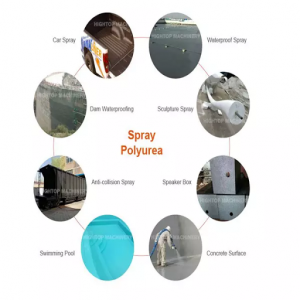

Utilized Areas